Know the Facts:

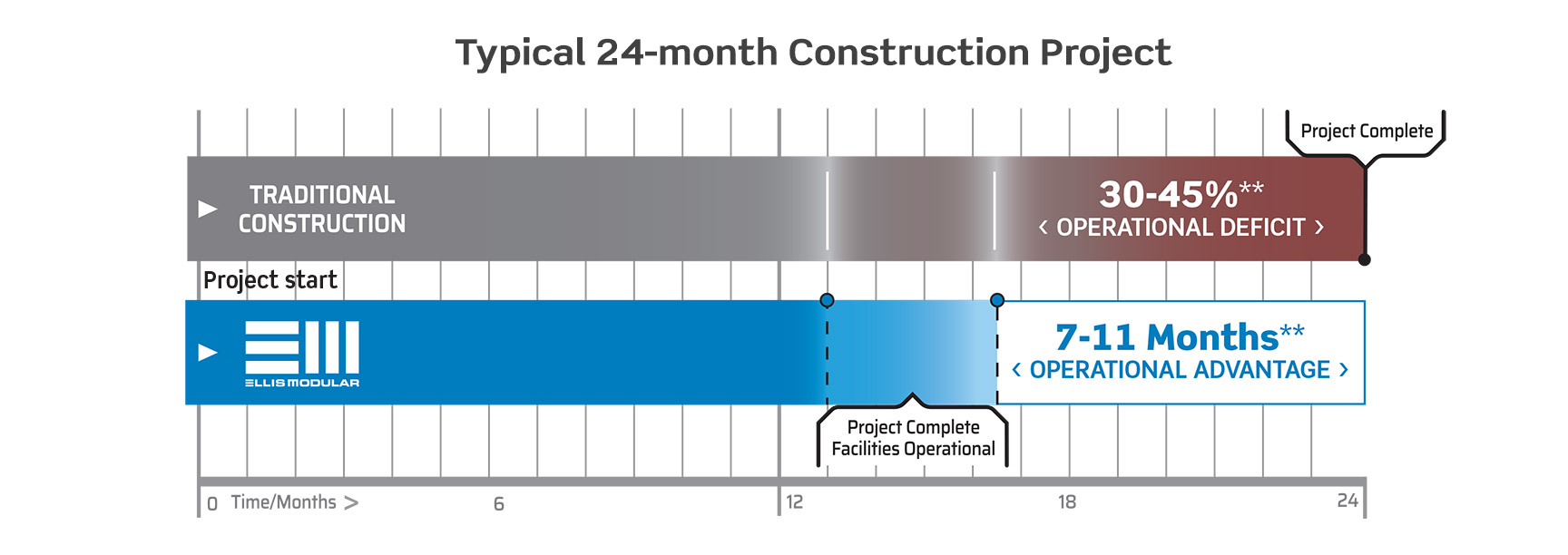

Modular vs Traditional Construction

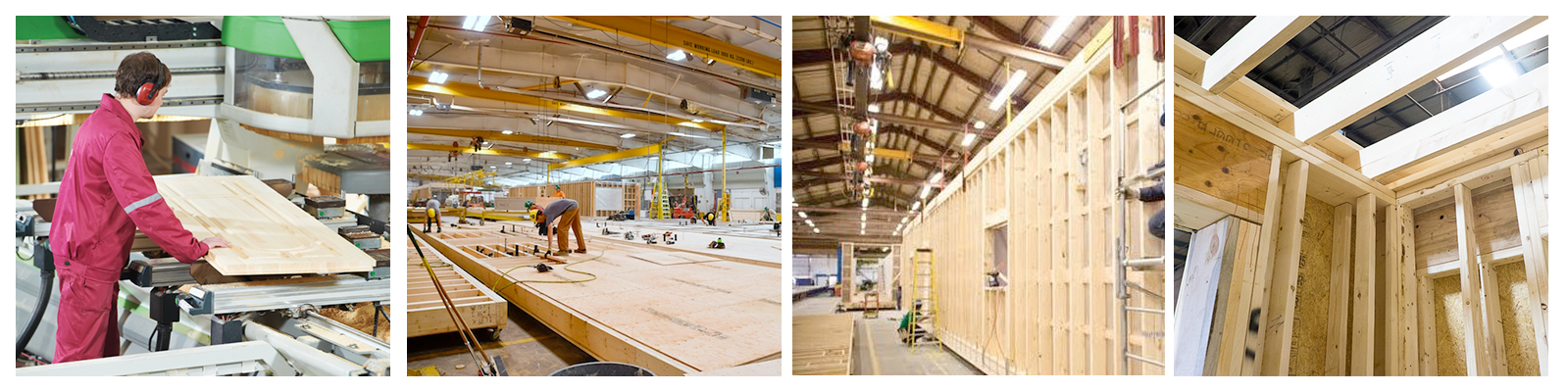

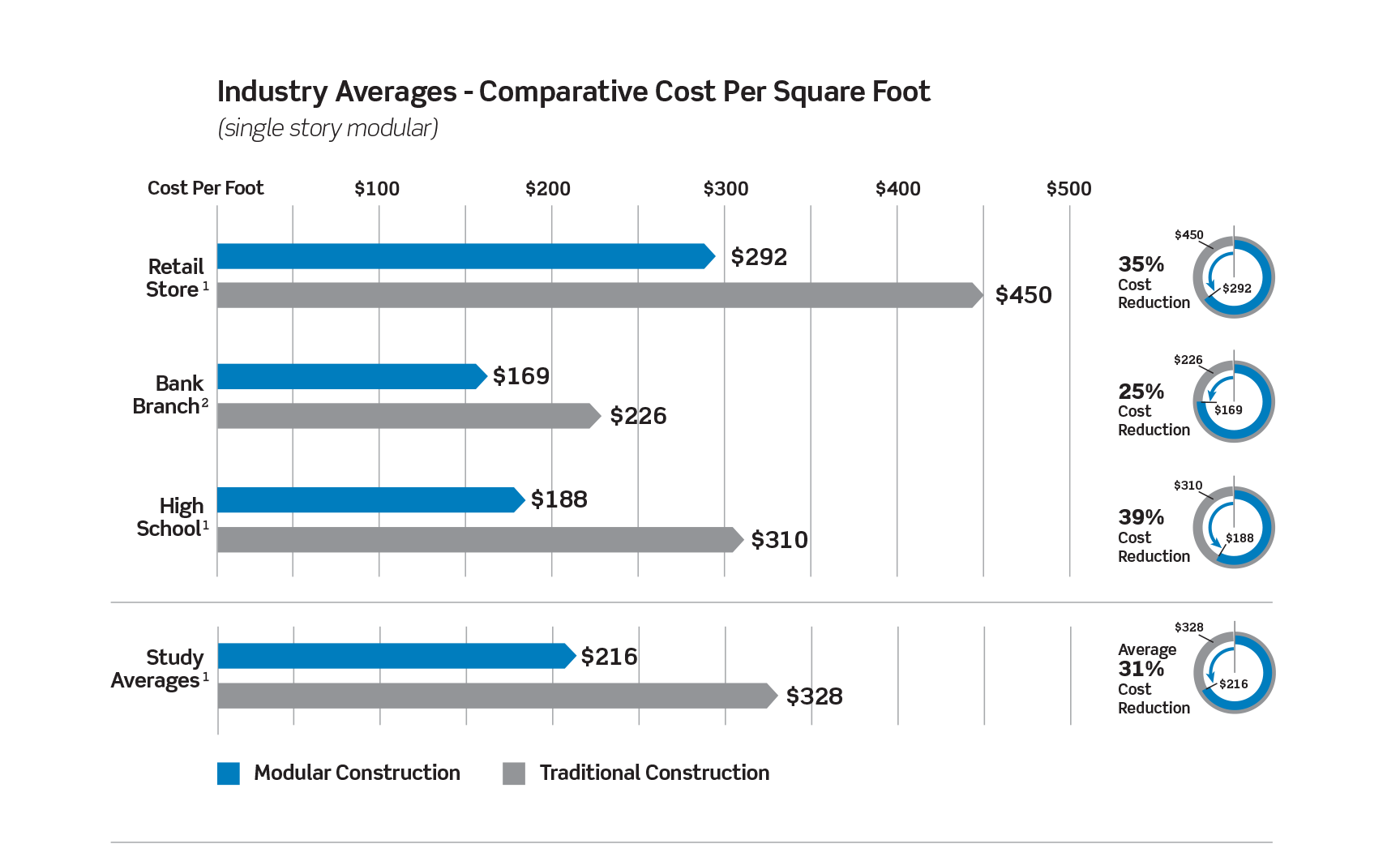

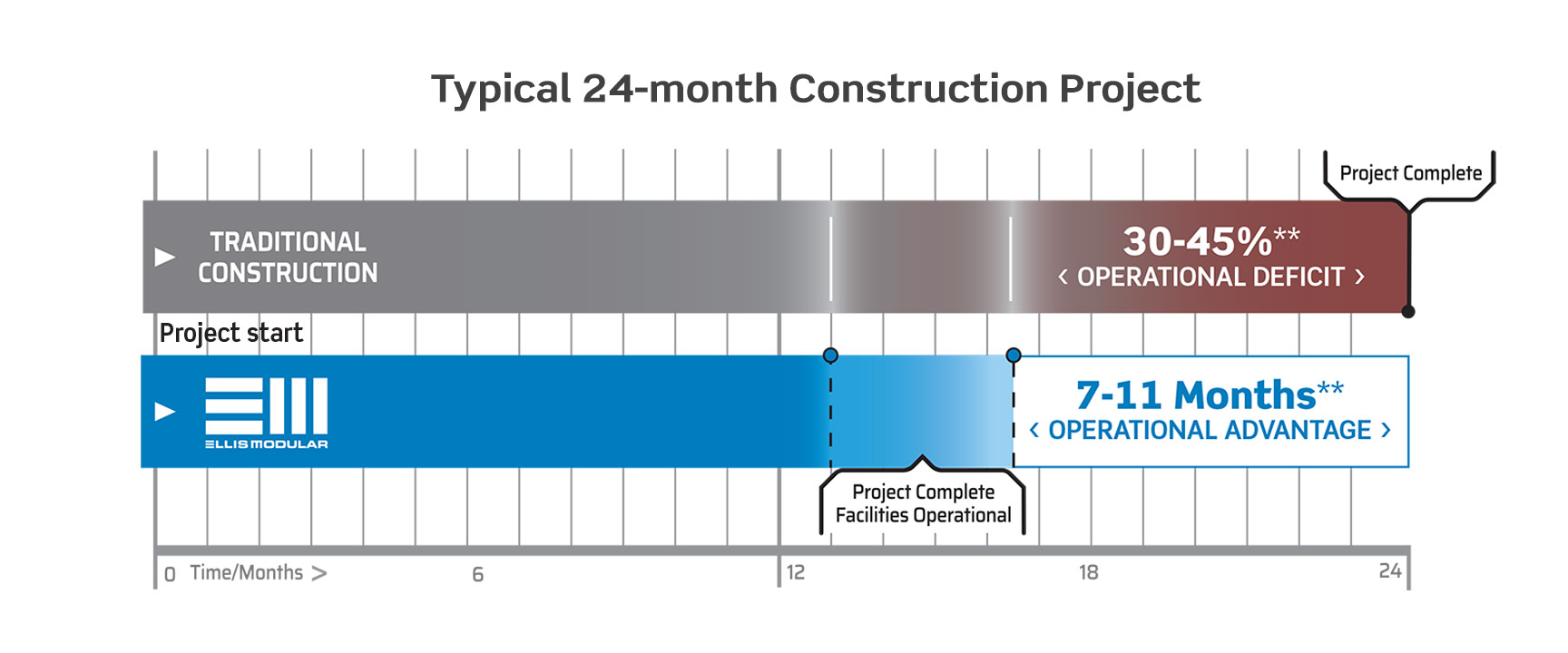

Pre-fabricated modular, on-site construction takes full advantage of what a controlled assembly environment has to offer. With this advantage comes savings in construction costs overall; time savings in planning, engineering and construction; avoidance of weather delays typical for site-built frame and stick construction; quality management of materials and assembly; reduced materials waste and cost; and increased safety by reducing on-site deliveries and construction traffic.

- Savings in construction costs overall

- Time savings in planning, engineering and construction

- Avoidance of weather delays typical for site-built frame and stick construction

- Quality management of materials and assembly

- Reduced materials waste and cost

- Increased safety by reducing on-site deliveries and construction traffic

- Less environmental impact due to less site traffic and construction equipment